Fabrication:

Entire steel fabrication as per approved designs of clients is carried out in our fabrication shop under the constant supervision of our production engineers. The sheet metal fabrication is done using the latest fabrication machines.

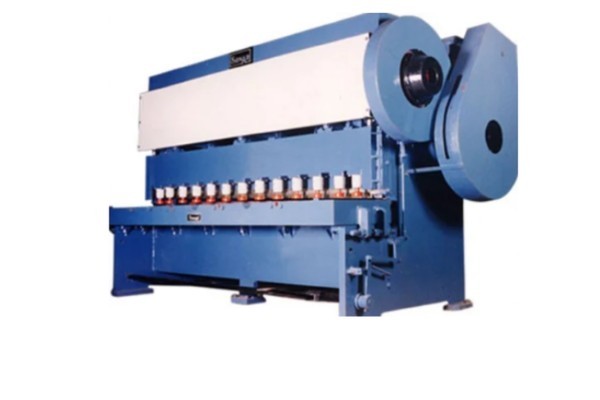

First, the M.S. sheets are cut on a 2500-mm-long guillotine shearing machine, followed by corner cutting and instrument cutouts done on a power press machine. Then these sheets are bent on a 2500-mm-long 50-tonne press brake and welded using arc welding and a Co2 welding chine. Each fabricated component is thoroughly checked before further release for painting or powder coating.

Pretreatment / Powder Coating / Painting:

The fabricated parts and panels go through the pretreatment processes of degreasing and derusting, phosphating, and passivation using the latest 8-tank process. Following the pretreatment process, an electrostatic gun powder coats the panel boards before baking them in the oven.

Assembly and wiring:

Assembly and wiring work is carried out in the area, which is separated from the fabrication and paint shop. Bus bars are bent by skilled fitters with the help of proper tools to give the correct radius so as to avoid any cracks in the bus bar material. Wiring is done by skilled wiremen. Thoroughly conversant with standard wiring practices.

Testing facilities:

With a view to ensuring that our products are of high quality, we got our products, such as PCC, tested at CPRI, Bhopal. We have equipped our factory with all the necessary equipment for carrying out our detailed routine tests of all the panels manufactured by us as well as for inward inspection of various components and materials purchased by us. All the panels manufactured by us are thoroughly tested before they are offered for external inspection, and all the routine tests are carried out as per the client's requirements in their presence before dispatch.